A Benchmark Conventional Dynamic Daylighting Configuration

Why a Conceptual Benchmark Configuration?

The conventional state of the art in dynamic daylighting technology is to link automated shading and lighting controls together in an integrated system. Unfortunately, the few dynamic daylighting systems available today are too expensive to be considered cost-effective for retrofit applications in the U.S.

However, these systems also offer features that go beyond dynamic daylighting, such as wireless remote control, premium-level shading aesthetics, integration with other building systems, and sophisticated control and user-interface software. And, not surprisingly, they also appear to be priced with relatively high mark-ups.

So existing products don't represent the maximum cost-effectiveness that could be achieved with conventional technology. Instead, a conceptual benchmark product—without these additional features, optimized for daylight-harvesting cost-effectiveness, and priced as aggressively as possible—is needed for a fair assessment of the technology's ultimate potential to penetrate the lucrative retrofit market.

Benchmark Architecture

Maximizing cost-effectiveness requires maximizing energy savings while minimizing the price to the end-user.

Fortunately, thanks to the ground-breaking research at Lawrence Berkeley National Laboratory, there's no mystery about how to maximize energy savings from dynamic daylighting: use motorized Venetian blinds and switchable/dimmable ballasts under hybrid open-loop/closed-loop control.

One way to reduce price is also straightforward: strip out features that aren't absolutely necessary for dynamic daylighting. However, identifying further opportunities for significant reductions requires an analysis of the price structure of available products. Such an analysis shows that the motorized blind is the most expensive portion of a lean "daylighting only" integrated system, and that prices quoted in a non-competitive environment have a much higher mark-up than high-volume products such as occupancy sensing light switches.

These observations point to what might be the most cost-effective way to implement dynamic daylighting with conventional technology:

- Use an interior-mounted horizontal blind as the system's shading device. Automate the blind with motor and control modules that can be field-retrofitted to existing blinds, leveraging their huge installed base.

- Use a hybrid open/closed-loop control protocol as demonstrated by LBNL: tilt the blind's slats to an angle that depends on the total illumination in the daylit area as sensed by a conventional WorkPlane Illuminance (WPI) sensor—but ensure that no direct sunlight is admitted by limiting the tilt range on basis of the solar azimuth and elevation.

- Interconnect the shading and lighting subsystems in each zone to share the WPI sensor and enable coordinated operation: when more illumination is needed, decrease the shading before increasing the lighting level; when less illumination is needed, decrease the lighting level before increasing the shading.

- Use Dimming-and-Switching (D&S) lighting control, rather than Dimming-Only (DO) control or Switching-Only control. D&S control saves significantly more energy than DO or SO control, but costs more. However, the additional cost of D&S control is swamped by the costs of automated shading, so its greater energy savings therefore provides the shortest overall payback period.

- Network the system between multiple daylit zones to share solar position (and optionally weather, diagnostic, and building-wide control) information, reducing the sensor cost per zone.

- Provide a user interface to enable occupants to adjust the shading manually.

The following chart shows such a configuration, with the elements associated with dynamic daylight control distinguished from those required for basic daylight harvesting:

Cost

Independent testing has demonstrated that dynamic daylighting systems like the one shown in Chart 1 save substantial amounts of energy, so the main issue with the commercial viability of such a system is cost.

Published estimates of the cost of conventional dynamic daylighting systems are in the context of new construction or major renovations, not retrofits to existing buildings. This is probably because costs are prohibitive in retrofit applications.

However, retrofits represent the greatest opportunity for near-term reductions in energy use--as well as the greatest near-term commercial opportunity for daylight harvesting. So the following discussion addresses the installed cost of conventional dynamic daylighting technology in retrofit applications.

Mark-Up

Current dynamic daylighting systems appear to have relatively high mark-ups, and installed system price appears to depend much more on per-project negotiations than is the case with higher-volume products. However, in order to provide a basis for assessing the technology's ultimate market potential, the costs discussed below assume mark-ups comparable to those of high-volume products such as fixed-brightness electronic ballasts and occupancy sensing light switches.

System Scale

Because the benchmark configuration of Chart 1 shares information across all the daylit zones in the host building, the cost per zone associated with generating that information (e.g. the cost of a roof-mounted solar position/irradiance sensor) decreases as the number of zones increases. This analysis assumes a system with enough zones to virtually eliminate this cost, so it's omitted from the estimates provided below.

Daylight Harvesting Costs

The lighting portion of the system of Chart 1 is a two-zone dimming-and-switching system with a single WPI sensor/controller shared between two luminaires, each equipped with its own relay and dimming ballast. Such a system is available off-the-shelf from several manufacturers.

Hardware Costs

Lighting controls such as that of Chart 1 are inexpensive and appear to have relatively low mark-ups. Single-unit retail costs for the lighting portions of the assumed configuration were obtained via a web search, with a 33% discount applied to reflect the cost in a large-scale project.

Installation/Commissioning Costs

One of the market issues with daylight-harvesting lighting controls is that they frequently fail to provide the expected savings. This is often attributed to a failure to properly "commission" (i.e. test and tune) systems after installation.

However, our own analysis indicates that inadequate commissioning is a much smaller issue than two other causes of poor performance: improper specification/installation (e.g. poor selection of photosensor type, mounting location, and orientation), and—especially—over-shaded windows.

Further, manufacturers of daylight-harvesting lighting controls have been steadily working to reduce their products' commissioning requirements, and the required commissioning labor for simple lighting controls like the one assumed in this analysis is minimal.

Total assumed labor (including installation, check-out, and commissioning) for the daylight-harvesting portion of the benchmark system is 0.9 hours.

Rebates

Rebate programs are widely available, but vary by utility and class of service. This analysis assumes what appears to be a typical rebate program, with a $20 credit per photosensor/controller and a $40 credit per dimming ballast. Thus, the system of Chart 12 qualifies for a total of $60 in rebates.

Illuminated Floor Area

The cost per square foot of a daylight-harvesting lighting system depends on the cost of the lighting control as well as the floor area illuminated by the controlled luminaire(s). The area illuminated by the luminaire, in turn, depends on the lamp/luminaire configuration and spacing.

This analysis assumes the most widely used lamp/luminaire configuration in existing office buildings: a two-foot by four-foot recessed parabolic troffer with three standard T-8 lamps, mounted on an eight-foot by ten-foot grid. Therefore, our cost estimate is based on median illuminated area of 80 square feet per luminaire, yielding an assumed floor area of 160 square feet for the two-zone system of Chart 12.

DDC Costs

As previously noted, the DDC costs represent all of the dynamic daylighting system costs beyond the costs of daylight harvesting alone, including costs of required augmentation of the daylight harvesting lighting system.

Hardware Costs

The assumed DDC hardware costs include 6 elements:

- An inexpensive off-the-shelf miniblind motor with built-in displacement encoder.

- A slat-tilt sensor (two-axis MEMS accelerometer) that can be attached to one of the blind's slats or (preferably) fixed to the tilt shaft within the headrail.

- A blind controller capable of servo-positioning the slats to arbitrary tilt angles in response to commands obtained via an 802.15 (e.g. Zigbee) RF interface. A reasonably full featured 8-bit microcontroller (e.g. an Atmel megaAVR) would be more than sufficient for this application.

- Ethernet and 802.15 interfaces (including physical layer and protocol stack) for the daylight-harvesting lighting controller.

- Increased microcontroller capacity in the daylight-harvesting lighting controller. This is assumed to require a step up in microcontroller class, e.g. from an Atmel megaAVR to XMEGA class).

- A handheld RF remote control. Because the system will already include an 802.15 link interconnecting the lighting and shading subsystems, the use of an 802.15-compliant RF remote is less expensive than the installed cost of a wired wall switch.

Installation/Commissioning Costs

The installation and commissioning costs for the DDC portion of the system are both significantly greater than those for the daylight-harvesting portion. The costs are dominated by the labor to automate the host blind, which includes the following steps:

- Preparation of the work area

- Removal of the host blind and securing it in a portable work fixture.

- Installation of the motor and controller within the blind's headrail, including trimming of the blind's tilt shaft.

- Attachment of the tilt sensor and alignment to ensure that its orientation accurately tracks that of the host blind's slats.

- Reinstallation of the blind.

- Installation of the low-voltage power cord and power supply.

- Clean-up

Total estimated labor for these steps is 1.6 hours, which is about 70% of the total DDC-related labor.

The next largest contributor to the labor cost is testing/commissioning, which includes the following steps:

- Relocation of commissioning equipment to the work area.

- Adjusting gain parameters to calibrate the inferred daylight illuminance against actual illuminance (performed in daytime and for "fully open" and "mostly closed" blind settings).

- Adjusting the slat-tilt limits to compensate for the presence of nearby shading/reflecting objects.

- Testing the complete system at multiple illuminance set-points (most likely using a test mode built-into the system that simulates the WPI sensor output for changing daylight conditions).

Total estimated testing/commissioning labor is 0.5 hours, which is about 22% of the total DDC-related labor.

Rebates

No prescriptive rebates are yet offered for DDC technology, presumably because its market penetration is so limited. So DDC systems currently qualify only for custom rebates, which pay much less than typical prescriptive rebates on a per-kWh/kW basis. The cost estimates below assume a typical custom rebate program which offers $0.05 per kWh saved and $50 per kW of peak demand reduction.

Sidelit Floor Area per System

The cost per square foot of the DDC portion of the system depends on the installed cost of the DDC equipment as well as the floor area sidelit by the host window. The sidelit area, in turn, depends on the miniblind width and window head height. The costs per square foot below are based on the estimated median blind width and window heat height in U.S. office buildings (6 feet and 9 feet respectively), resulting in a median DDC aperture area of 54 feet. The total sidelit area is assumed to be three times this aperture area, or 162 square feet—about the same as the 160 square feet for the two luminaires assumed for the two-zone daylight-harvesting lighting system.

Overall System Costs

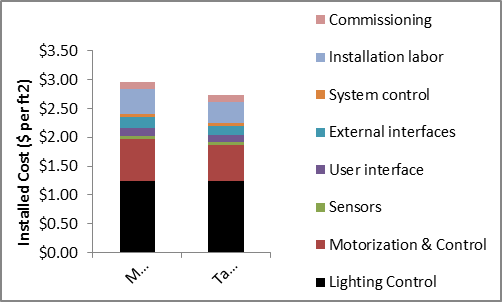

The following chart provides a breakdown of the estimated median retrofit costs of the benchmark dynamic daylighting system of Chart 1, without rebates:

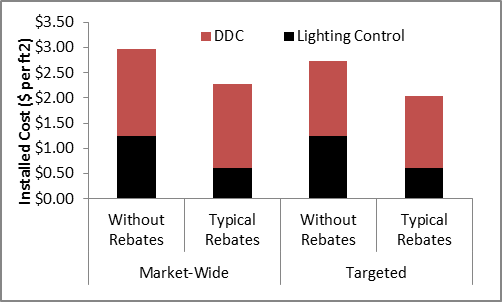

The following chart shows the total estimated median cost with and without rebates:

Chart 3: Median Projected Retrofit Costs of Benchmark System, With and Without Rebates

Virtually every daylight harvesting installation in the U.S. will qualify for some type of incentive program, so the "with typical rebates" costs shown above are more representative of the real-world costs of daylight harvesting.

Savings

Daylight harvesting saves dollars in two ways: by reducing energy (kWh) consumption charges, and by reducing peak demand (kW) charges. The total dollar savings will depend on numerous installation-specific factors, the most important of which are the baseline lighting Energy Use Intensity (EUI), the local utility rate structure, and the degree of baseline window over-shading.

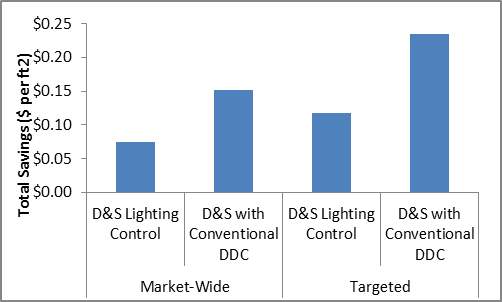

Taking these variables into account, the following chart shows the median projected dollar savings in U.S. office buildings from a dynamic daylighting system like the benchmark system of Chart 1, along with the savings from the same type of daylight-harvesting lighting control without DDC:

While DDC doubles the median savings, it also reduces the savings variance. This benefit, which isn't reflected in Chart 4, is probably nearly as important as payback period from the standpoint of gaining mainstream market acceptance.

Market Potential

Conventional dynamic daylighting technology has two major advantages in seeking market acceptance: it overcomes the well-recognized problem of over-shaded windows in exploiting daylight harvesting's full potential in existing buildings, and its effectiveness and occupant-friendliness have been proven through independent research.

However, it also faces two market hurdles: it requires that shading and lighting subsystems be capable of "talking" with each other, and--even more importantly--its retrofit payback period is almost an order of magnitude too long to be considered cost-effective for mainstream use.

The Interface Issue

Unfortunately, there's no single, "industry standard" protocol for how different building subsystems should interface and interoperate. Instead, there are a variety of competing standards. At the networking level, there's Ethernet, ARCnet, LonTalk, and MS/TP over twisted-pair wiring—not to mention 0-10 VDC analog control and DALI (Digital Addressable Lighting Interface). Above that, at the application/control level, there's BACnet, LonWorks, OPC, and others.

Until a single industry standard emerges, would-be manufacturers and distributors of conventional DDC technology are stuck in a dilemma. If they commit to a single standard, they risk giving up potential market share due to incompatibilities. On the other hand, if they try to accommodate multiple standards, they're forced to dilute their resources. The only way out of this dilemma is to try to sidestep the standards issue altogether by offering turn-key "system-of-systems" solutions (as Lutron has done with their Quantum™ offering, and as Zumtobel has done with LUXMATE). But that forces them to straddle the lighting, shading, and (potentially) HVAC industries—not just in design and manufacturing, but also in marketing, distribution, installation, and maintenance.

One implication of the interface issue is that would-be buyers or distributors of integrated dynamic daylighting technology may be forced to take on the role of prime contractors or system integrators, as the New York Times Company did—or else turn to a company that has the resources to provide a turn-key solution, such as Lutron or Zumtobel AG.

Excessive Payback Period

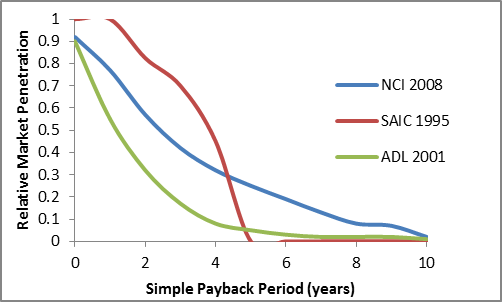

An energy saving retrofit's simple payback period—equal to its initial cost divided by the dollar value of its annual energy and demand savings—is the most important determinant of its market potential.

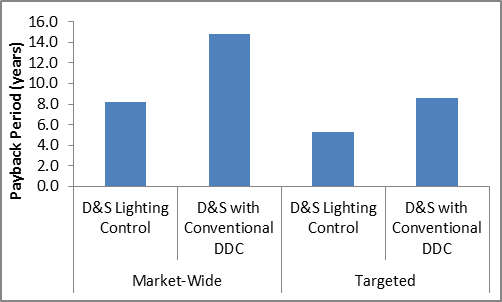

The following chart shows the projected median retrofit payback period of a dynamic daylighting system like the benchmark system of Chart 8, along with that of the same type of daylight-harvesting lighting control without DDC:

Despite doubling the median savings, conventional DDC technology is so expensive that it actually lengthens the payback period for daylight harvesting. Even worse, the median payback period with conventional DDC—even in the most cost-effective "targeted" installations—is longer than what the market is willing to accept.

That's evident from a glance at published market penetration models for non-residential energy saving technologies, which typically estimate the penetration as a function of the simple payback period. The three most frequently cited models are illustrated in the following Chart:

So, even if conventional dynamic daylighting technology weren't complex and difficult to distribute, its high cost represents an enormous hurdle in achieving mainstream market acceptance.

Summary of Key Points

- Currently avilable Dynamic Daylight Control (DDC) systems include features that go beyond dynamic daylighting and are priced with relatively high mark-ups

- So, a hypothetical benchmark configuration is necessary for a fair assessment of the potential cost-effectiveness of DDC systems based on conventional technology

- Such a benchmark system has six key attributes:

- Use of an interior-mounted horizontal miniblind as the shading device, with the motorization components retrofitted into an existing blind

- Use of hybrid open/closed loop control to provide accurate daylight regulation while minimizing the risk of glare

- Interconnection of the shading and lighting subsystems in each zone to enable coordinated operation

- Sharing of the control functionality and most expensive sensors by networking the system between multiple zones

- Use of dimming-and-switching control to maximize the additional savings provided by the relatively expensive DDC capability

- Inclusion of a simple user interface to allow local control of the shading and lighting settings, minimizing the risk of occupant alienation

- As with any energy saving retrofit technology, the costs and (especially) the savings from such a system will vary with many installation-specific variables. In installations conducive to the shortest paybacks,

- Median installed price (with typical rebates) is $2 per square foot, with the DDC portion of the system representing 80% or $1.60 of the total

- Median savings (including both consumption and demand savings) are $0.024 per square foot

- As a result, the median payback is about 8.6 years

- While the payback period of such a system is about half that of off-the-shelf dynamic daylighting systems, it's still more than a factor of two too long to achieve significant market penetration. And, as with off-the-shelf systems, the need for integration between the various components presents challenges for distribution