The Conventional State of the Art in Dynamic Daylighting

Genesis of Conventional Dynamic Daylighting Technology

The basic ideas underlying today's dynamic daylighting technology date back at least to the 1960's.

For example, U.S. patent 3,294,152 to Kuijvenhoven (1966), shows a motorized roller shade controlled by a photosensor mounted to sense the admitted daylight reflected from an interior surface. The disclosure includes one of the first published rationales for Dynamic Daylight Control (DDC) in office buildings:

- "In modern buildings, windows are of large area and there is a requirement for preventing excessive admission of radiation from the sun so that the heat and light conditions in rooms can be kept within the limits necessary for comfortable living and efficient working conditions."

- "An office worker, for example, will require a light intensity of say 500 lux on his desk, supplied either by natural or artificial means."

- "The natural light may vary from 0 to 100,000 lux (of which only 500 may be needed)."

- "The artificial light may give, for example, 500 lux as required but the power used to produce this, as well as the incidental heating, is wasteful if natural light is excluded at the same time".

While the patent was directed to a DDC system (i.e. photocell-controlled shade) per se, the disclosure also introduces the idea of coordinated operation between a DDC and lighting system to minimize net energy consumption:

- "...the curtain control system could then be combined with an artificial light control system so as to utilize artificial light under some conditions"

- "Heat retention at night, when required, can be achieved by interconnecting the curtain control and an artificial light switch, so that when the light is switched on the curtain is drawn to cover the window".

However, despite a flurry of DDC-related patents in the 1960's, none of the disclosed systems were commercialized in the U.S., ostensibly because of low energy costs and the control limitations of analog electronics.

LBNL's Prototype Systems

Development of dynamic daylighting technology got another boost from the "original" energy crisis of the early 1970's, which stimulated extensive research to increase energy efficiency in U.S. non-residential buildings. Much of that research was done at what is now the Environmental Energy Technologies Division (EETD) of the Lawrence Berkeley National Laboratory (LBNL). LBNL researchers were the first to thoroughly investigate the potential of dynamic daylighting to optimize the net energy performance of buildings.

Through the 1980's and early 1990's, the LBNL research was limited to analysis and simulations. But in the mid-1990's--ostensibly because of the advent of inexpensive PC-based data-acquisition hardware, microcontrollers, and dimmable electronic ballasts for fluorescent lamps--the research graduated to testing of prototype dynamic daylighting systems in partial-scale and full-scale settings. These tests were the first to conclusively demonstrate the energy savings potential of dynamic daylighting, and the research reports remain a rich source of objective information on the design and performance of such systems. And despite being developed almost two decades ago, LBNL's prototype systems still represent the conventional state-of-the-art in dynamic daylighting technology.

Integrated Architecture

LBNL's prototype systems used an integrated architecture in which the shading and lighting functions are linked together under common control, as shown in the following simplified diagram:

To facilitate this kind of integration, LBNL also developed a networking technology for low-level building control applications. This Integrated Building Environmental Communications System (IBECS) interconnects addressable nodes via a low-bandwidth 1-Wire™ network (Lee et al. 2003). Despite the current proliferation of standards for low-bandwidth wireless networking (e.g. Zigbee), a wired technology like IBECS still offers significant cost advantages for a room-sized network like that depicted in Chart 1, particularly for new construction (vice retrofits).

Shading Device

For their initial prototype system, LBNL researchers modified an off-the-shelf motorized horizontal blind to create what they called the Automatic Venetian Blind, or AVB (systems based on ElectroChromic (EC) Smart Window technology were also developed, but the bulk of the reported data is for AVB-based systems).

Conventional motorized blinds are typically designed for coarse, infrequent adjustments of the slat tilt angle, while (depending on the control protocol) DDC can require frequent small adjustments. LBNL researchers overcame this problem by replacing the blind's motor control circuit with a custom design capable of fine adjustments (Lee et al. 1998, pp. 6-7).

Control Protocol

LBNL's system used a hybrid open-loop/closed-loop control protocol in which the shading and lighting are adjusted on the basis of conditions outside, as well as inside, the daylit area.

Open-Loop Response to Outside Conditions

One of the advantages of horizontal blinds is that their slats can be tilted to block direct sun while still admitting diffuse daylight. The slat tilt angle necessary to block direct sun depends on the elevation angle of the solar disc, so LBNL's prototype system included a means of determining the sun's position relative to the window, as well as of accurately measuring the slat tilt angle:

- Originally, a prototype sun position sensor was used to directly sense the position of the sun (DiBartolomeo et al. 1996, p. 4). In a later iteration of the system, a computer estimated the solar elevation as a function of the time, window orientation, and local geographic coordinates (Lee et al. 1998).

- Likewise, two means were used to determine the tilt angle of the slats: an early version of the system relied on careful calibration of the slat tilt versus motor position (DiBartolomeo et al. 1996, p. 3), while a later system employed a MEMS accelerometer affixed to one of the slats to directly sense the tilt (Lee et al. 2003, p. 6).

Based on the position of the sun relative to the plane of the window, such a system "knows" when admission of direct sun is geometrically possible. Under such conditions, LBNL's system restricted the slat tilt range for DDC operation to angles which blocked rays from the known solar elevation.

No Direct Sky View

Blocking of direct sunlight isn't enough to ensure the absence of glare; hazy skies or bright clouds can also cause uncomfortable visual conditions. One way to mitigate this risk is to further restrict the slat tilt range to never allow a direct view of the sky from the daylit zone. Initial testing of LBNL's prototype system (in a partial-scale test facility) used the whole tilt range, but later testing in a full-scale private office used a restricted "no sky view" tilt range for better glare control. The researchers estimated that the restricted tilt range reduced the energy savings by ~34% on partly cloudy to overcast spring days (Lee et al. 1998, page 13).

Closed-Loop Response to Inside Conditions

While the range of slat tilt angles for LBNL's control protocol was determined by outside conditions (i.e. the sun's position), the tilt angle within that operating range was determined by conditions within the daylit area.

A conventional WorkPlane Illuminance (WPI) sensor was positioned to measure the total illuminance (including both daylight and artificial light) at the center of the workplane in the sidelit area. The system then adjusted the lighting level and the slat tilt in response to the WPI roughly as follows:

- When WPI was greater than the set-point, the system reduced the brightness of the lights; once the lights were fully off, the system tilted the slats to reduce the daylight level.

- When WPI was less than the set-point, the system tilted the slats to admit more daylight; once the slats were fully open (or the "direct sun" tilt angle limit had been reached), the system increased the brightness of the lights.

Performance

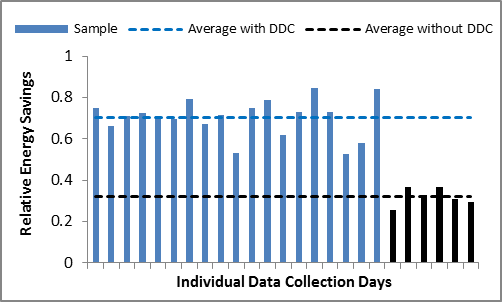

Testing showed that LBNL’s prototype systems could save much more energy than the same daylight-harvesting controls without DDC, without distracting the building occupants or compromising the quality of their visual environment. For example, the following chart shows the savings observed in a partial-scale test-bed:

Commercialization Potential

With basic R&D completed and key implementation lessons learned, LBNL began efforts to encourage commercialization of dynamic daylighting technology.

However, LBNL estimated the simple payback period at 10 years (Lee et al. 1998, page 19), which was then—and remains today—about three times too long to appeal to investors in non-residential energy efficiency.

The LBNL researchers observed that

- "Industry adoption of this technology has proved to be difficult because the technology spans multiple separate and distinct industries: envelope systems, electric lighting systems and control systems" (ibid.), and

- "We view the motorized system as the primary market barrier to widespread adoption in U.S. commercial buildings" (ibid., page 20).

Dynamic Daylighting Today

Despite the passage of nearly two decades since the demonstration of LBNL's prototype systems, dynamic daylighting today remains a niche technology, at least in the U.S. Only two manufacturers seem to offer such systems off-the-shelf, and they appear to be used in only a few newly constructed or fully renovated "statement" buildings. Two of the most prominent installations are described below.

NY Times Headquarters Building

Perhaps the most prominent dynamic daylighting installation in the U.S. is in the new, 1.5 million ft2 New York Times Headquarters Building, completed in 2007. The system's design, acquisition approach, and performance have been documented and published online.

System Configuration

The system uses an integrated architecture and control protocol similar to those of LBNL's prototype systems—except that it employs motorized roller shades, rather than motorized venetian blinds. Shade deployment is automatically adjusted as a function of the solar elevation angle to shield the occupants from direct sun, while otherwise maximizing natural illumination. The system is controlled by off-the-shelf automation hardware and software, but with custom control rules and algorithms. NYT has expressed willingness to make these algorithms available for use in other projects.

The system also includes a user interface to enable occupants to manually adjust the shading when desired. The LBNL researchers who were involved in post-occupancy evaluation of the system strongly advocate inclusion of such controls in all dynamic daylighting systems to boost occupant acceptance (Lee et al. 2013, page 62).

Acquisition Approach

This was literally a ground-breaking project in several respects. Construction of the building was preceded by a field test of candidate shading and lighting products in a 4,300 ft2 mock-up facility. The field test was sponsored by government agencies and implemented jointly by LBNL and The New York Times Company (NYT), with involvement from manufacturers of equipment under consideration for use in the completed building.

Based on the results of the field test, LBNL and NYT were able to produce a balanced system specification that NYT knew would result in the desired illumination and energy saving performance, and that manufacturers knew would be achievable within the required cost and schedule. A project of such magnitude probably would not have been feasible in the USA without the risk reduction provided by the field test.

Nevertheless, NYT was apparently not able to find a prime contractor to bid on the entire system. Instead, NYT took on additional risk by effectively acting as prime contractor, purchasing some of the equipment directly and awarding separate contracts for installation of the shading equipment, lighting controls, and lighting fixtures. Because of the size of the project, NYT was able to negotiate a substantially lower price for the lighting controls, ostensibly reducing the price for subsequent purchasers.

Performance

The annual savings in lighting Energy Use Intensity (EUI) due just to the dynamic daylighting system were 38% relative to a similar building compliant with the energy efficiency code then in effect, ASHRAE 90.1-2001 (Lee et al. 2013, page 61). These savings substantially underestimate the savings achievable with a blind-based (rather than shade-based) dynamic daylighting system in a typical retrofit today, for three reasons:

- Per ASHRAE 90.1-2001, the assumed baseline building included both scheduling and occupancy controls. Some of the energy saved by such controls could also be saved through daylight harvesting, so the observed savings would have been greater relative to a building without them. And, even today, buildings that are candidates for energy saving retrofits typically lack at least one of these controls. Even if a retrofit includes both scheduling and occupancy sensing controls in addition to daylight harvesting, a portion of the overlapping savings is attributable to daylight harvesting.

- More importantly, the sidelit floor area over which the savings were measured extended inward for up to 4.2 window-head-heights, which is substantially deeper than is typically the case for sidelit systems. Actual savings were undoubtedly much greater over the more typical sidelit zone extending inward just 2 window-head-heights.

- Finally, as noted previously on this page, a blind-based dynamic daylighting system (such as LBNL's prototype) will save more energy year-round than a shade-based system.

Our analysis indicates that the latter two factors alone account for a 50% reduction in the savings, so the reported 38% savings is consistent with 75–80% savings from a blind-based system in the prime sidelit area extending inward just two window-head-heights from the window.

Unfortunately, the published reports do not address the savings attributable just to the DDC (automated shading) portion of the system, because all of the sidelit areas in the building were equipped with automated shades.

Impact

Thanks to the scope and depth of the field test—and the thoroughness with which technical details of the project have been documented—the New York Times Headquarters Building has undoubtedly reduced the risk assocated with large-scale daylighting projects.

However, the project also illustrates that, until recently, substantial expertise in daylighting—as well as the resources and willingness to act as prime contractor or system integrator—were necessary prerequisites for acquisition of integrated dynamic daylighting systems in the U.S.

Fortunately, at least one U.S. company—Lutron Electronics, Incorporated, who participated in the project—now offers all the components necessary for an integrated dynamic daylighting system, as well as the software and hardware to tie it all together. Lutron's Quantum™ system integrates their established EcoSystem™ lighting control technology with their Sivoia QED™ motorized shading products, providing the same type of functionality as the system acquired by NYT.

Torre Espacio, Madrid

The Torre Espacio (Space Tower) in Madrid, Spain (completed in 2008) uses an integrated dynamic daylighting system similar to LBNL's prototype system, but on a massive scale.

Based on the LUXMATE Professional lighting control architecture offered by Zumtobel AG, the system includes more than 13,500 individually addressable dimming ballasts and 4,500 motorized blinds, along with a roof-mounted LUXMATE Skyscanner daylight sensor that accurately senses the intensity and spatial distribution of the daylight incident on the building.

Unlike LBNL's prototype system, this LUXMATE installation provides purely open-loop control of the admitted daylight, but like LBNL's system, it is capable of blocking direct sun while admitting diffuse daylight.

Substantial information on Zumtobel's LUXMATE system can be found on the internet. For example, Zumtobel has an excellent brochure on the use of LUXMATE for dynamic daylight control, which can be found via online search. However, no independently collected data on the system's actual performance seems to be available.

Summary of Key Points

- The basic ideas underlying today's dynamic daylighting technology date back at least to the 1960's, but the first practical systems were prototyped at Lawrence Berkeley National Laboratory (LBNL) in the late 1990's

- LBNL's systems used an architecture in which the shading and lighting functions are linked together under common control to form an integrated dynamic daylighting system

- Despite the passage of almost two decades, the LBNL prototype systems still represent the conventional state-of-the-art, and all of the dynamic daylighting systems currently available (or already in use) use a similar configuration

- The first and highest-profile dynamic daylighting installation in the USA is in the New York Times Headquarters Building, completed in 2007. The New York Times Company effectively acted as its own prime contractor, issuing multiple contracts for acquisition and installation of the system components. One of the contractors, Lutron Electronics, Inc., now offers a similar dynamic daylighting system off-the-shelf

- Another high-profile installation is in the Torre Espacio in Madrid, completed in 2008. The building uses an off-the-shelf dynamic daylighting system offered by Zumtobel, AG